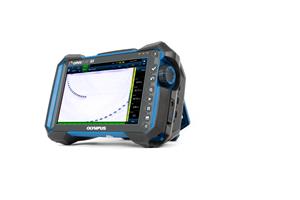

OmniScan® X3 Flaw Detector Redefines the Standard for Phased Array

WALTHAM, Mass., Oct. 30, 2019 (GLOBE NEWSWIRE) -- OmniScan® instruments are recognized globally as the benchmark for portable phased array ultrasonic testing (PAUT) thanks to their power, reliability and ease of use. The new OmniScan X3 flaw detector elevates the standard with innovations that improve the entire inspection workflow. Setting up for a job is faster and more efficient while total focusing method (TFM) images collected through full matrix capture (FMC) give users more confidence in their decision making. When an inspection is complete, leading-edge software tools make analysis and reporting easier.

The OmniScan X3 flaw detector combines the essential tools needed for PAUT inspections, such as TOFD, two UT channels, eight groups and 16:64PR, 16:128PR and 32:128PR configurations*, with powerful innovations, including:

- TFM/FMC with 64-element aperture support

- Improved phased array imaging, including an innovative live TFM envelope feature

- Acoustic influence map (AIM) simulator for TFM mode

- 25 GB file size

- Up to 1,024 × 1,024-pixel TFM reconstruction and four simultaneous, live TFM propagation modes

- Simplified user interface with onboard scan plan

- Wireless connectivity to the Olympus Scientific Cloud™ (OSC) makes it simple to keep the instrument’s software up to date

The comprehensive onboard scan plan tool enables users to visualize the inspection, helping reduce the risk of errors. The entire scan plan, including the TFM zone, can be created in one simple workflow. Creating a setup is also faster with improved calibration tools and support for simultaneous probe and beam set configuration, onboard dual linear, matrix and dual matrix array creation and automatic wedge verification.

Certified IP65 dust proof and water resistant, the instrument has the reliability and ease of use that OmniScan flaw detectors are known for combined with high-quality images that help make interpreting flaws more obvious. With the total focusing method, users can produce geometrically correct images to confirm the characterization of flaws identified through conventional phased array techniques and obtain better images throughout the volume of a part. Additional features that enable outstanding images include a 16-bit A-scan, interpolation and smoothing and a vivid 10.6-inch WXGA display that provides clarity and visibility in any light.

The OmniScan X3 flaw detector makes analysis and reporting faster, both onboard the instrument and on a PC. The instrument also comes with a variety of helpful data interpretation tools:

- Circumferential outside diameter (COD) TFM image reconstruction to facilitate interpretation and sizing of long seam weld indications

- Merged B-scan to facilitate the screening of phased array weld indications while keeping the workflow simple

Whether inspecting pipes, welds, pressure vessels or composites, the OmniScan X3 flaw detector enables users to complete their work efficiently and interpret flaws with confidence.

For more information about OmniScan flaw detectors, visit www.olympus-ims.com.

*The 16:64PR configuration limits the number of groups to 1 TOFD, 2 PA and 2 TFM.

About Olympus

Olympus is a global technology leader, crafting innovative optical and digital solutions in medical technologies; life sciences; industrial solutions; and cameras and audio products. Throughout our nearly 100-year history, Olympus has focused on being true to society and making people’s lives healthier, safer and more fulfilling.

Our Industrial Solutions Business is committed to the safety and betterment of society through the pioneering, development and manufacture of world-leading test and measurement solutions. These solutions are used in industrial and research applications ranging from aerospace, power generation, petrochemical, civil infrastructure, automotive and consumer products. For more information, visit https://www.olympus-ims.com.

Olympus…True to You. True to Society. True to LIFE.

Olympus and OmniScan are registered trademarks, and Olympus Scientific Cloud is a trademark of Olympus Corporation.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/79292d42-3ff4-44f2-b5b2-f4a8ae3d4b98

Media Contact: Hilary Banda 781-419-3624 Hilary.Banda@olympus-ossa.com

Buy photo and video packages at flexible prices

Para pagos desde Argentina, tomamos el precio a la cotización del día del dólar oficial del Banco Central de la República Argentina

- 50 Photos + 30 Videos - U$D 900.00

- 100 Photos + 100 Videos - U$D 2250.00

- 500 Photos + 400 Videos - U$D 6230.00